Facilities

Labs

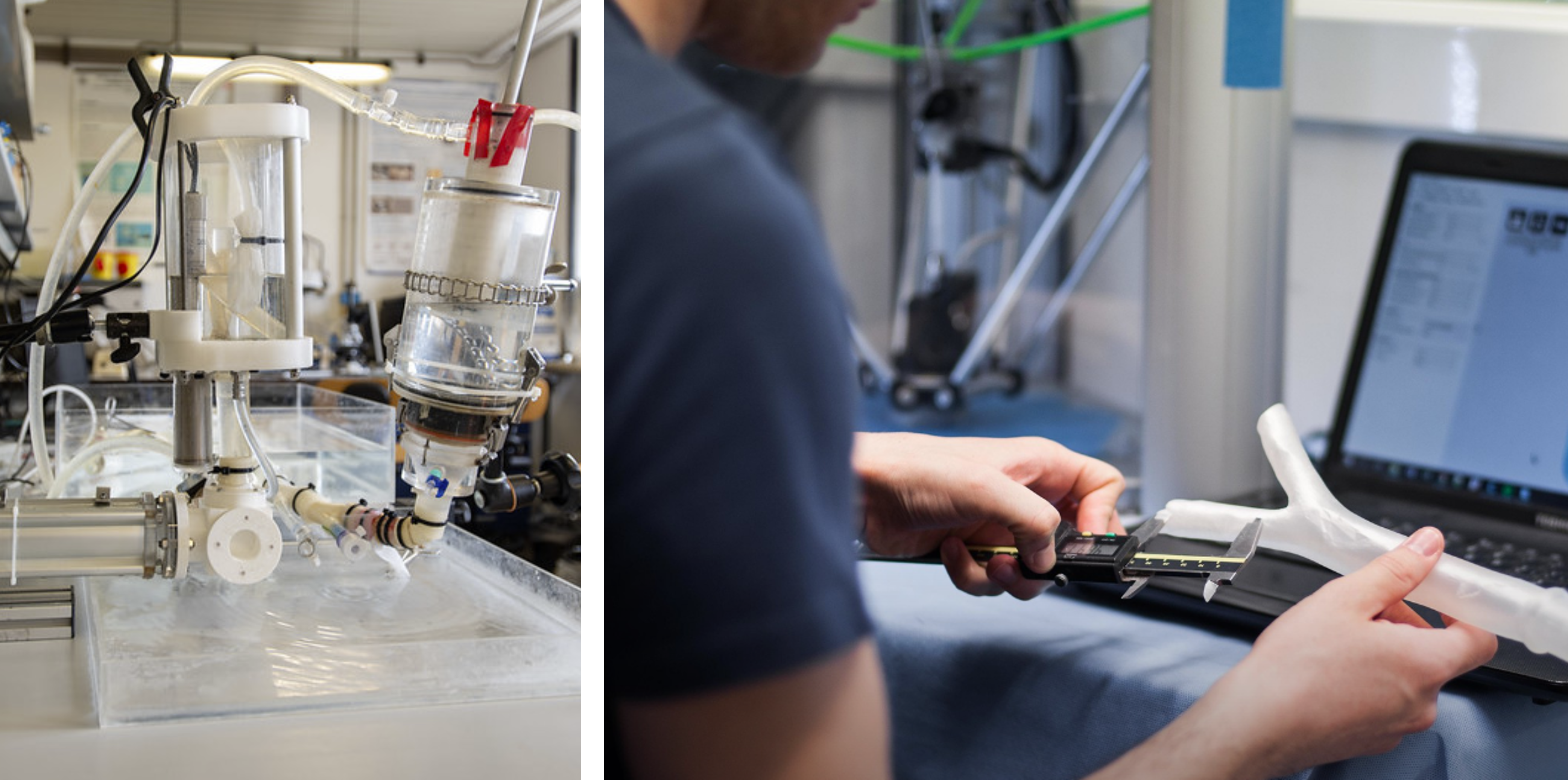

Laboratory of Experimental Micro and Biofluid dynamics (µBS Lab)

It is located at the premises of the Department of Electronics, Information and Bioengineering, in the main Polimi Campus.

The mission of the laboratory is to carry out research and teaching in the fields of in-vitro biofluid-dynamics and development of devices interacting with biological fluids and tissues. In line with these activities, µBS Lab provides the Biomech group with multipurpose fluid-dynamic bench testing capabilities, representing the main support environment for the assessment of our thematic laboratories’ technological developments.

Research at µBS Lab is carried out in close contact with laboratories of excellence at other PoliMI Departments and with National and International research centers. Continuous collaborations with Italian and International biomedical industries also take place, particularly in the fields of blood processing apparatuses and devices for cardiovascular surgical/interventional corrections.

Lab activities of the Biofluid-dynamics Laboratory teaching course takes place entirely at µBS Lab, as well as other lab activities pertaining to some other teaching courses of the Master’s Degree Program in Biomedical Engineering.

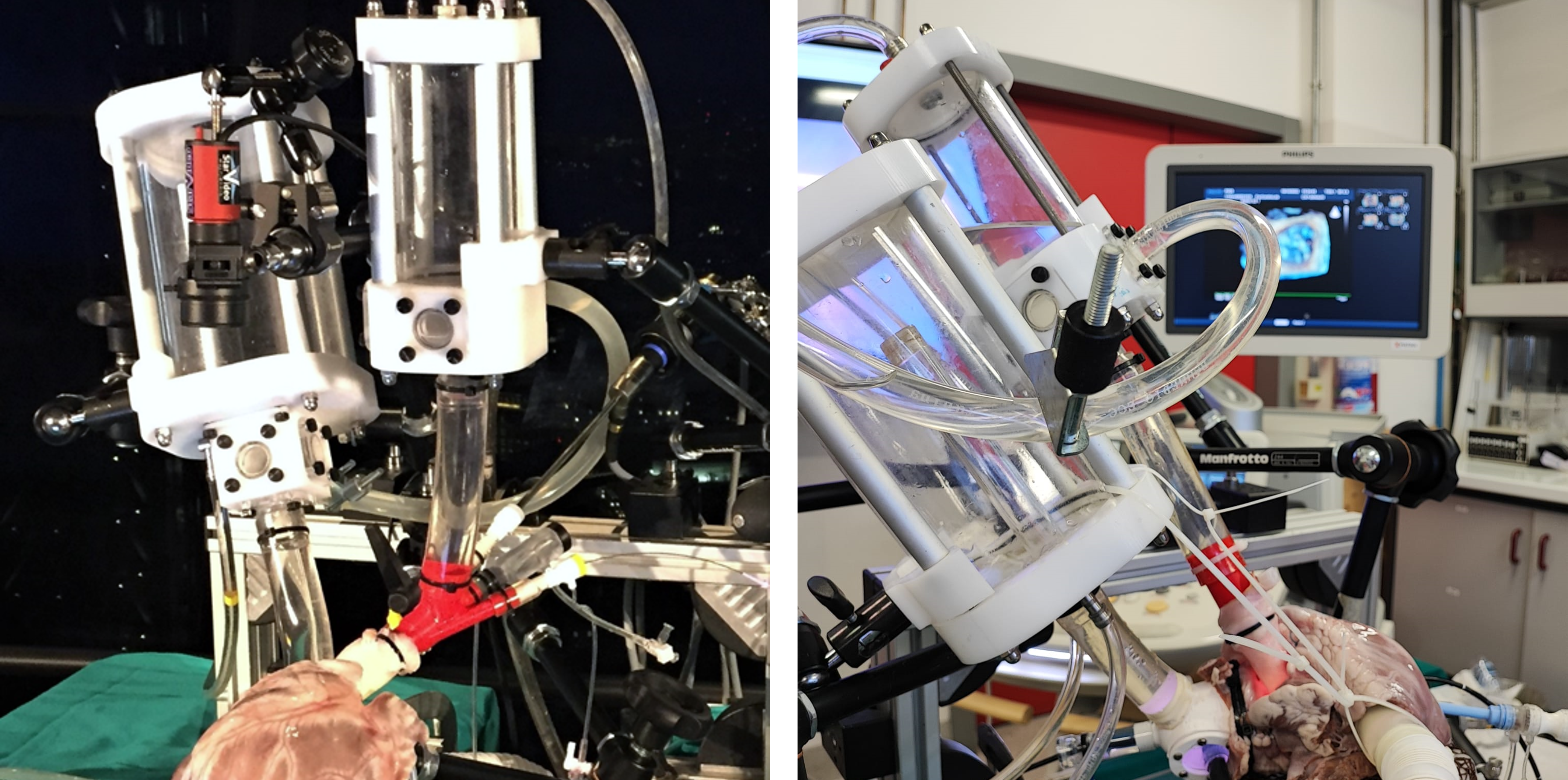

FoRCardioLab

The laboratory was founded in 2006 thanks to the “Foundation for Research in Cardiac Surgery”, as a joint initiative of PoliMI Biomedical Engineering staff and Cardiac Surgery Division at the “Luigi Sacco” hospital in Milan. It is now located at “Ca’ Granda Ospedale Maggiore Policlinico” hospital, in central Milan.

The laboratory is based on a strong collaboration of PoliMI researchers with the cardiac surgeons working at the Cardiac Surgery Division of the hospital. The activities of the laboratory are mostly related to in-vitro / ex-vivo testing of techniques and implantable devices for cardiac surgery and interventional cardiology.

The experimental activities are carried out with owned apparatuses, purposely developed for exploiting the use of excised animal samples within artificial mock loops, a research topic of which we are a recognized pioneering group at international level. Consistently with the most recent advances in the

field, transcatheter and minimally invasive approaches are now a main focus of the lab’s activity, which includes the setting of customized mock loops for industrial R&D.

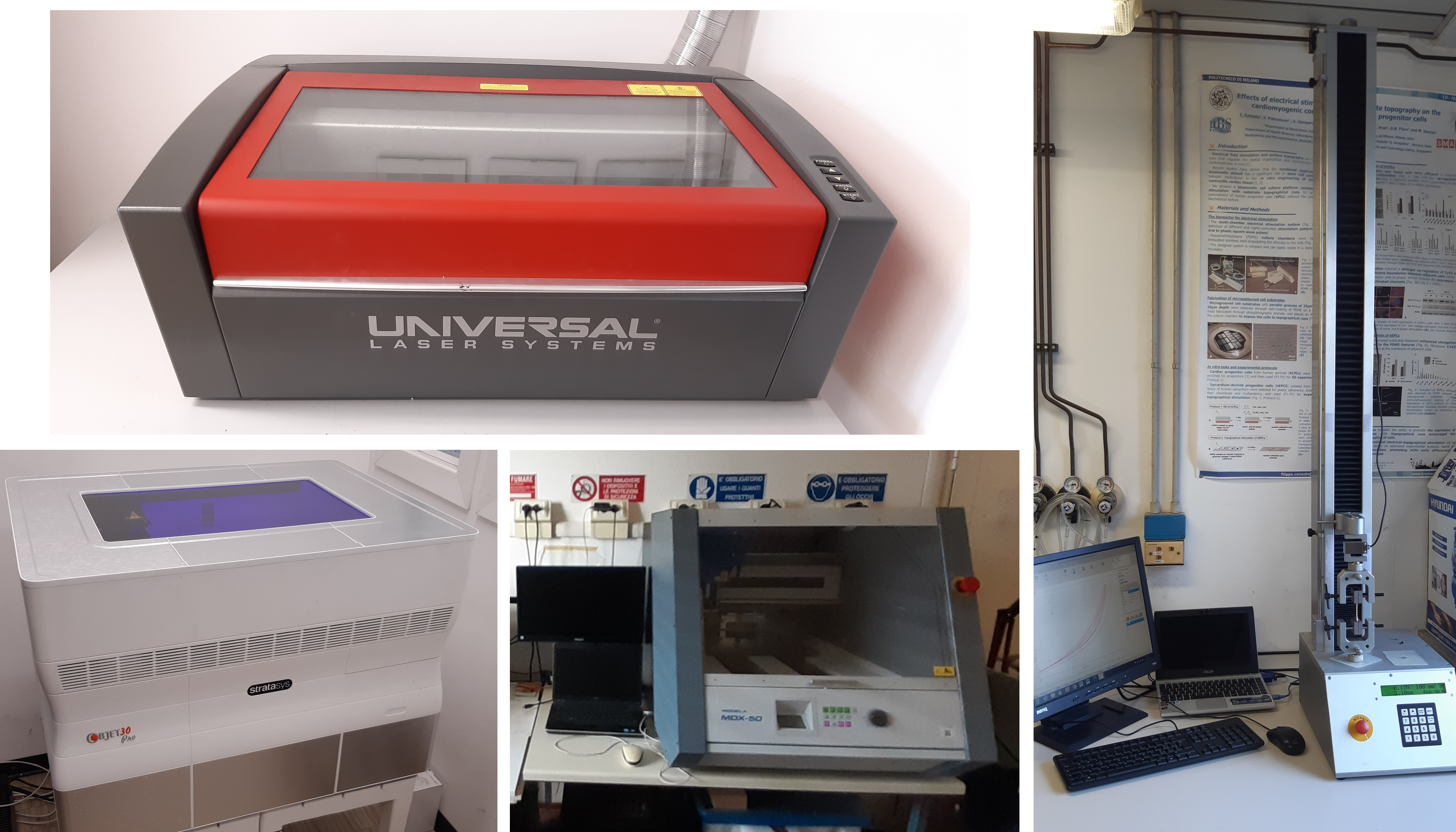

Prototyping Facilities

The µBS Lab is endowed with owned rapid prototyping facilities which support the manufacturing needs for the two laboratories and for the whole group’s research purposes.

- Polyjet 3D printing: one Stratasys Objet30 Prime V5 with build size of 294mm x 192mm x 149mm, layer thickness of 16µm

- FDM 3D printing: two Ultimaker 3 dual extruder 3D printer, with heated printing surface of 215mm x 215mm.

- Subtractive CNC prototyping: two Roland Modela CNC milling machines – one MDX-50 (working volume of 400mm x 305mm x 135mm, resolution of 0,001 mm/step); one MDX-40A (working volume of 305mm x 305mm x 105mm, resolution of 0,002 mm/step)

- Laser cutting: two Universal Laser System laser processing machines – one VersaLaser VLS3.50 (50 W – 10.6 µm CO2 source, working volume of 610mm x 305mm x 100mm); one VersaLaser VLS2.30 (25 W – 10.6 µm CO2 source, working volume of 406mm x 305mm x 102mm)

- Material testing: one AML Z3-X1200 Universal tensile testing machine with 1200 mm travel, 3kN max. force, 0.15 µm position resolution, 0.025-700 mm/min speed range